- ZK

- Guangdong, China

- 7-15days

Model No.: ZK300-4T-7.5GB/11PB

ZK300-P Solar Pump Inverter is a high-quality product widely used for AC 110/220V pumps. It enables photovoltaic and grid connection, making a significant contribution to achieving environmentally friendly energy.

invert solar inverters solar pump invert solar invert system solar pumping inverter water pump invert

ZK300-P Solar Pump Inverter Overview

The ZK300-P solar pump inverter utilizes solar and grid inputs, particularly MPPT function to ensure stable power output of the pump. Moreover, it is equipped with multiple protection mechanisms to ensure reliable and stable operations. As a result, the ZK300-P solar pump inverter is an efficient, practical, and environmentally friendly solar pump controller, highly recommended for use.

drive solar pump controller inverter manufacturing ac motor controller

ZK300-P Solar Pump Inverter Enjoy The Green-carbon Life

ZK300-P Solar Pump Inverter Features

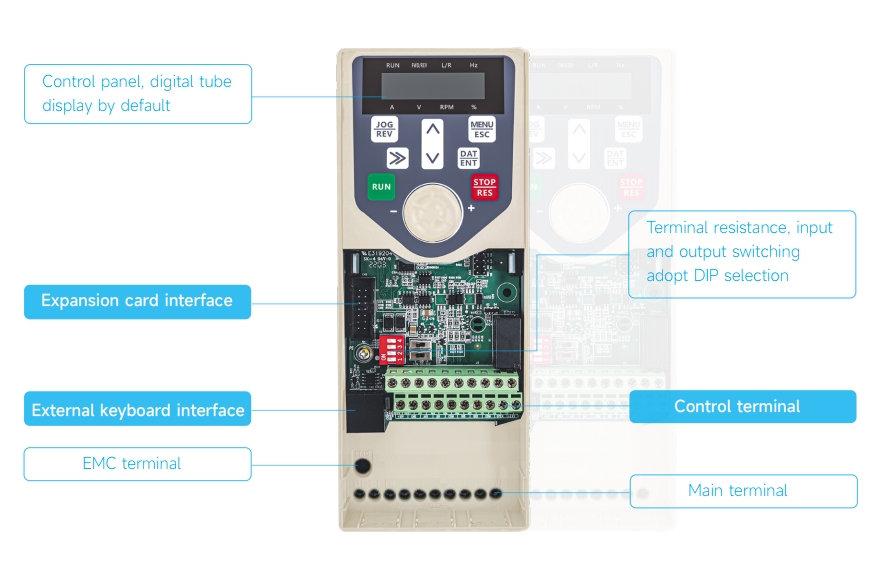

※ Compact structure, stable and reliable

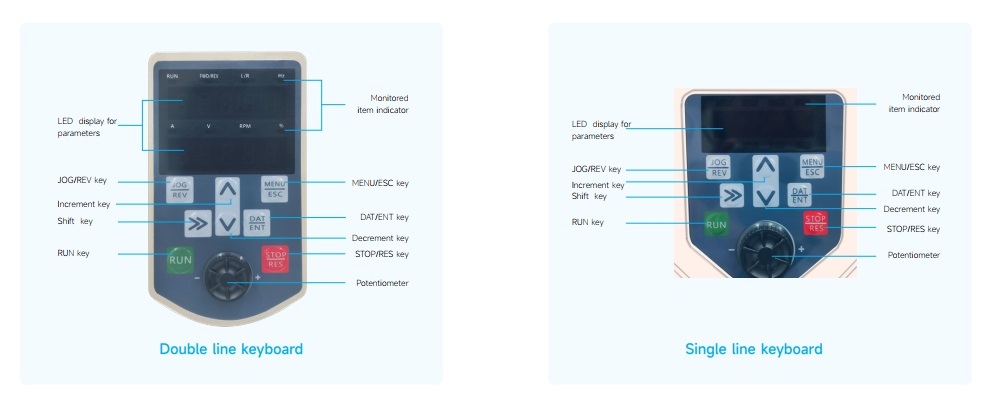

※ Keyboard operation

A newly designed panel keyboard with superior operability. Built-in keyboard and external keyboard support dual line display(control right can be selected through the drive parameters built-in or external keyboard).

※ Advanced heat dissipation design

Wide tooth surface heat dissipation and high wind speed design. Ensure the full power range drives can be used without derating of at high temperature.

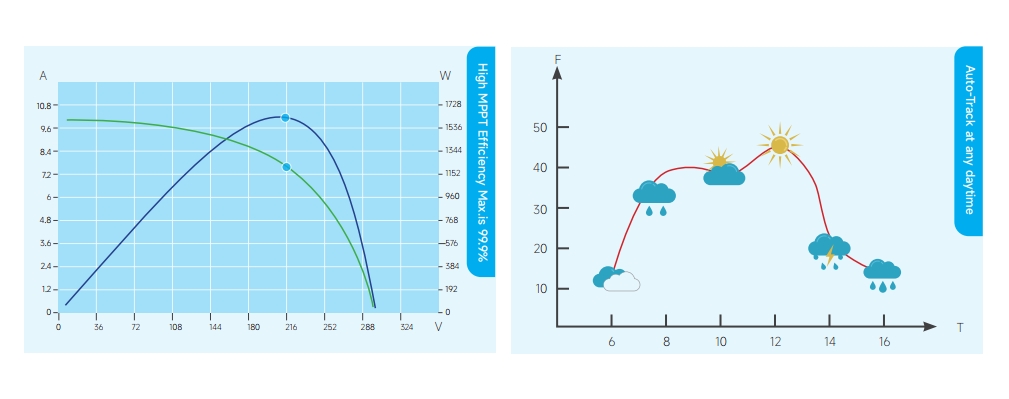

※ Advanced MPPT Technology

By continuously adjusting the output voltage and current of the inverter to match the maximum power point at the current light intensity, the maximum MPPT efficiency can reach 99.9%.

※ Driving Multiple Types of Pumps

Compatible with synchronous machine and asynchronous machine,energy-saving transformation is effortless.

※ High Performance & Multi-functions

- One-Key Operation

Just RUN it for AM pump system; Just RUN it after self-tuning for PMSM pump system.

- Special Functions

● Low frequency

● Dry run

● Over current of pump

● Minimum power

● PQ curve

● Dormancy

※ Maintenance Tools

Complete monitoring,configuration, optimization and diagnostic services are provided by FGAppStudio running on PC tool.

※ Intelligent monitoringbrings smart irrigation

- Custom PQ curve

Automatically calculate the parameters most concerned by users based on the curve, such as flow speed, daily flow, cumulative flow, daily power generation, and cumulative power generation.

- Intelligent IOT system

IOT data platform, wireless transmission technology(GPRS, Bluetooth or WlFl), intelligent judgment of needs for water and fertilizer for achieving smart irrigation.

※ Remote control of mobile APP can be controlled home

● Bluetooth, WIFI and GPRS wireless transmission

● Technology. Widely-used multi-language switching.

● Digital display Of current data are clear and accurate.

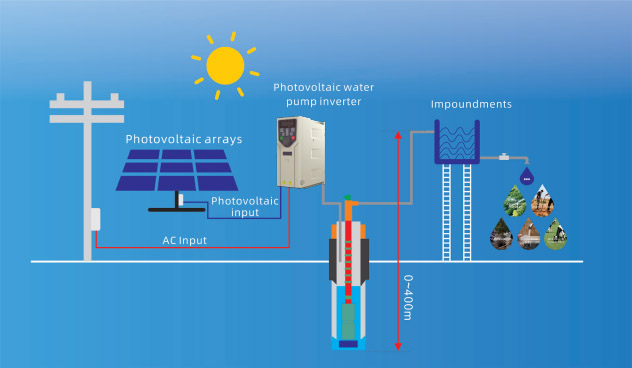

ZK300-P Solar Pump Inverter Application

Solar Pumping Inverter application system

ZK300-P solar pump inverter is commonly used in agricultural irrigation, residential water, landscape fountains, swimming pool water supply, desert management, Industrial Application, Drip irrigation& sprinkler ,Tank/ cistern filling, Rural water supply for ranches, cabins and cottages etc.

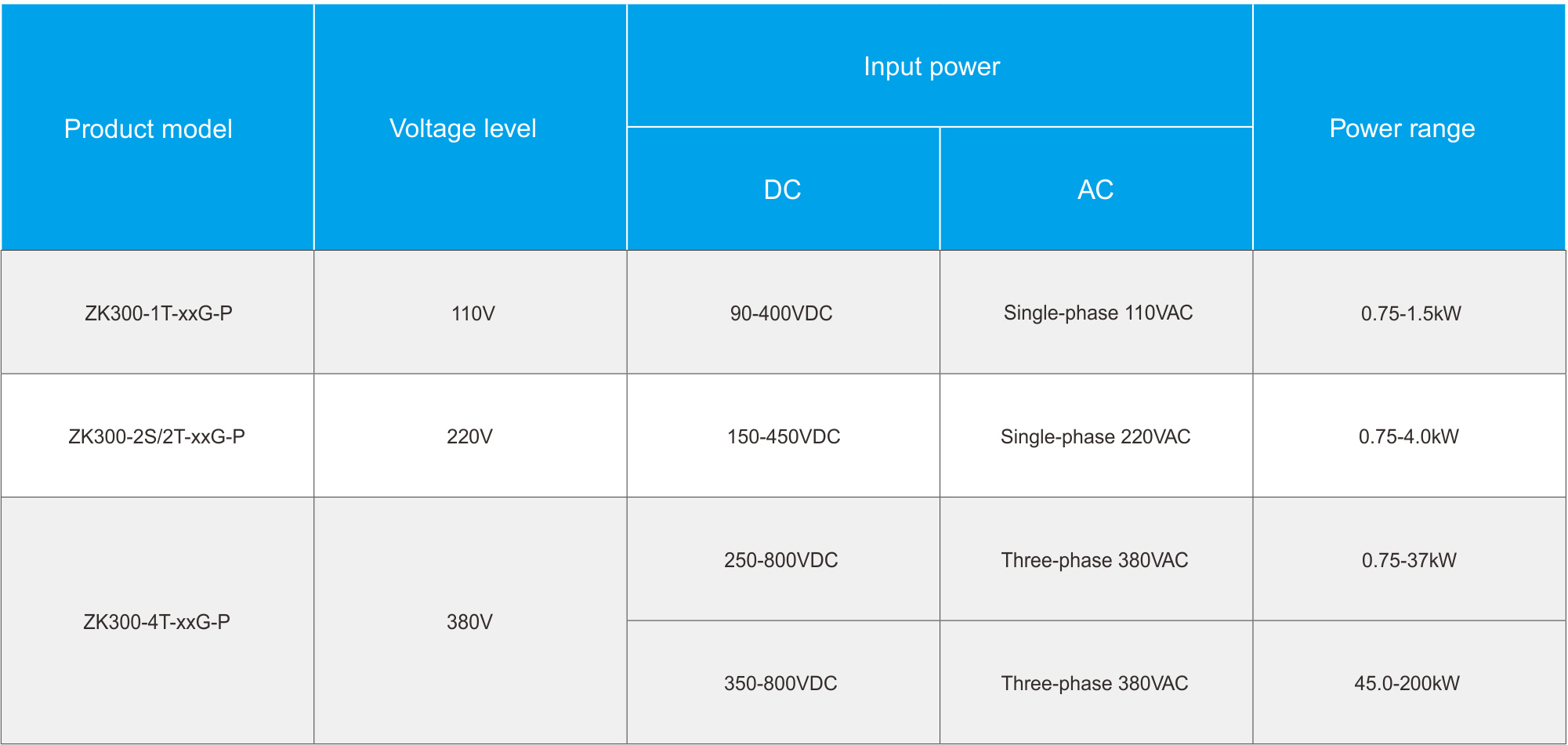

ZK300-P Solar Pump Inverter Technical Specifications

| Items | Specifications | |

|---|---|---|

Power input | Voltage | 1T: 90VDC to 400VDC S/2T: 150VDC to 450VDC 4T: 250VDC to 800VDC/350VDC-800VDC |

| Frequency | 50Hz/60Hz, Tolerance ±5% | |

Voltage range | Continuous voltage fluctuation ±15% short fluctuation -15%~+15% | |

| Voltage out-of-balance rate<3% | ||

Total Voc range (V) of recommended panels | 1T Type: 175-380VDC 2S/2T Type: 360-430VDC 4T Type: 620-750VDC | |

| Power output | Adaptive motor type | three-phase asynchronous motor Permanent magnet synchronous motor |

| Output voltage (V) | three-phase: 0% ~ rated input voltage,error < ±3% | |

Output frequency(Hz) | 0.00% ~ 599.00Hz; Unit: 0.01Hz | |

| Overload capacity | 150% rated current/1 min 180% rated current/10s 200% rated current/0.5s | |

| Basic functions | ACC/DEC time | 0.0 ~ 30000s |

| Switching frequency | 0.5kHz ~ 16kHz | |

| Frequency setting | Digital setting + control panel, Communication, Analog setting, Terminal pulse setting | |

Motor start-up methods | Started from starting frequency,Speed tracking start | |

| Motor stop methods | Ramp to stop, Free stop | |

| Protection function | Solar pump protection function | Dry run, Low frequency, Low power, Dormancy, Water full, Pump over current protection |

Basic protection function | Inverter unit protection, Overcurrent during acceleration, Overcurrent during deceleration, Over current at constant speed, Overvoltage during acceleration, Overvoltage during deceleration, Overvoltage at constant speed,Undervoltage, Power input phase loss, Power output phase loss, Inverter overload, Motor overload, Current detection fault, Inverter temperature exceeds the limit, Load becoming 0 , Too large speed deviation, Short circuit to ground, External equipment fault, Fast current limit fault, Communication fault, Master slave control communication disconnection, EEPROM read-write fault, PID feedback lost during running, Data storage fault, Control power supply fault, Motor switchover fault during running, Accumulative running time reached | |

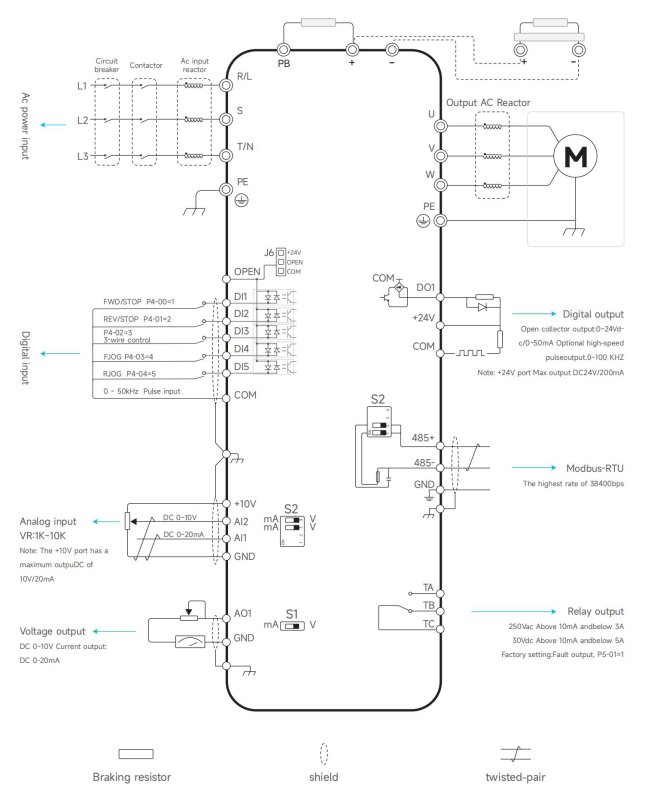

Communication network | Supports 485/Modbus protocol, Profibus-DP protocol, CANopen protocol, Profinet protocol, EtherCAT protocol, Modbus TCP protocol and CAN customized protocol | |

| Featured functions | Parameter copy, parameter backup, common DC bus, free switchover between two motors’ parameters, flexible parameter displayed & hidden, various master & auxiliary setting and switchover, flying start, a variety of Accel/Decel curves optional, brake control, 16-step speed control programmable (2-step speed supports flexible frequency command), wobble frequency control, fixed length control, count function three history faults, over excitation brake, over voltage stall protection, under voltage stall protection, restart on power loss, skip frequency, frequency binding, four kinds of Accel/Decel time, motor thermal protection, flexible fan control, process PID control, simple PLC, multifunctional key programmable, droop control, autotuning, field-weakening control, high-precision torque restraint, V/f separatedcontrol | |

| Environment | Place of operation | Indoors, no direct sunlight, free from dust, corrosive gases, flammable gases, oil mist, water vapor, water drop or salt, etc. |

| Altitude | 0~2000m. De-rate 1% for every 100m when the altitude is above 1000 meters | |

Ambient temperature | -10℃~ 50℃ , The rated output current should be derated 1% for every 1℃ when the ambient is 40℃~ 50℃ | |

| Relative humidity | 0~95%, no condensation | |

| Vibration | Less than 5.9m/s² (0.6g) | |

Storage temperature | -20℃~ +60℃ | |

Others | IP grade | IP20 |

| Cooling method | Forced air cooling | |

ZK300-P Solar Pump Inverter Model Analysis

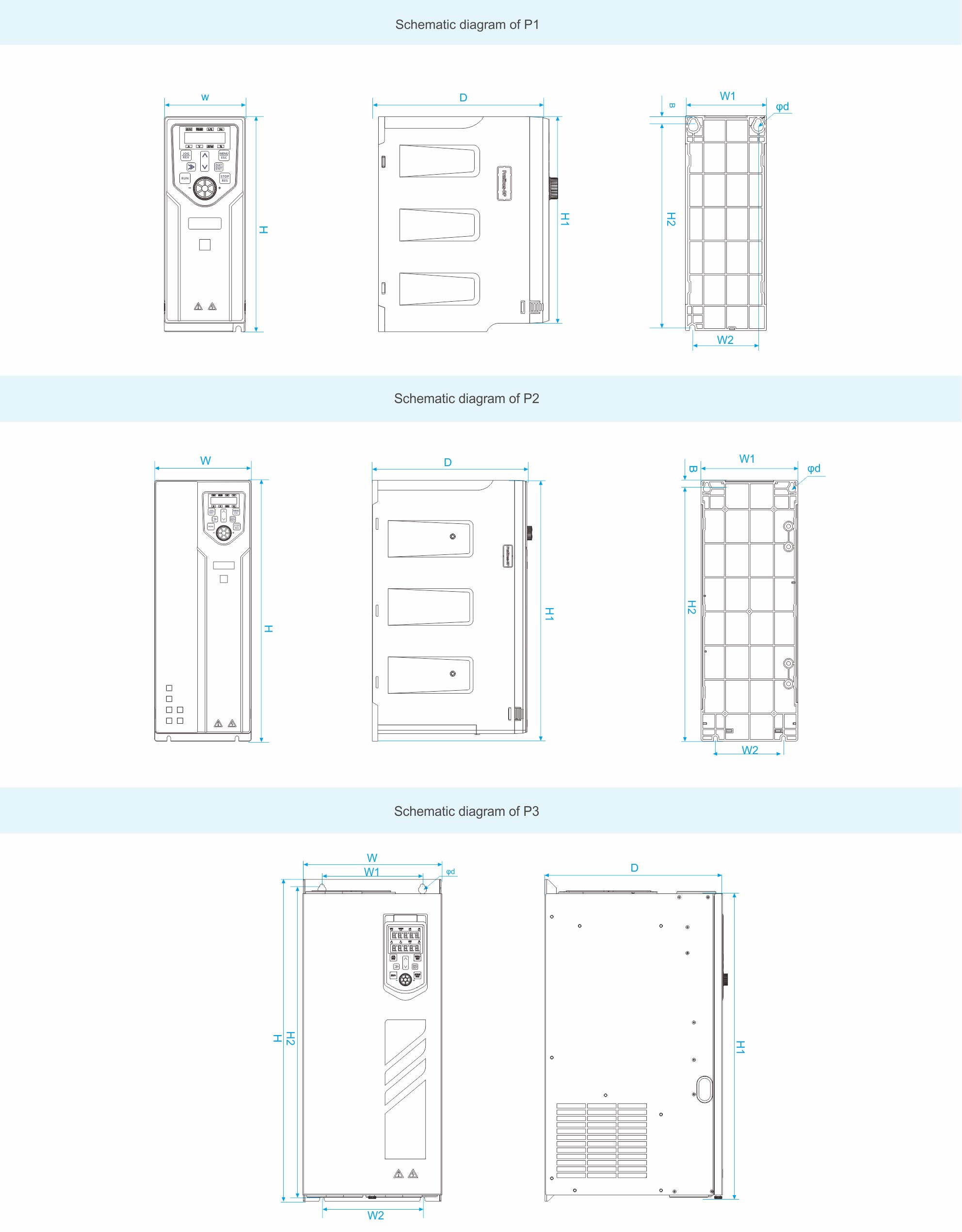

ZK300-P Solar Pump Inverter Installation Dimension Drawing

ZK300-P Solar Pump Inverter Standard Wiring Diagram

invert solar inverters solar pump invert solar invert system solar pumping inverter water pump invert solar water pump vfd solar solar invert vfd